Imagine a world where your clothes need to be more stylish and intelligent enough to interact with your devices or even monitor your health.

Sounds fascinating. Researchers at the University of Cambridge have brought us closer to this reality by developing a groundbreaking smart fabric created using industrial looms.

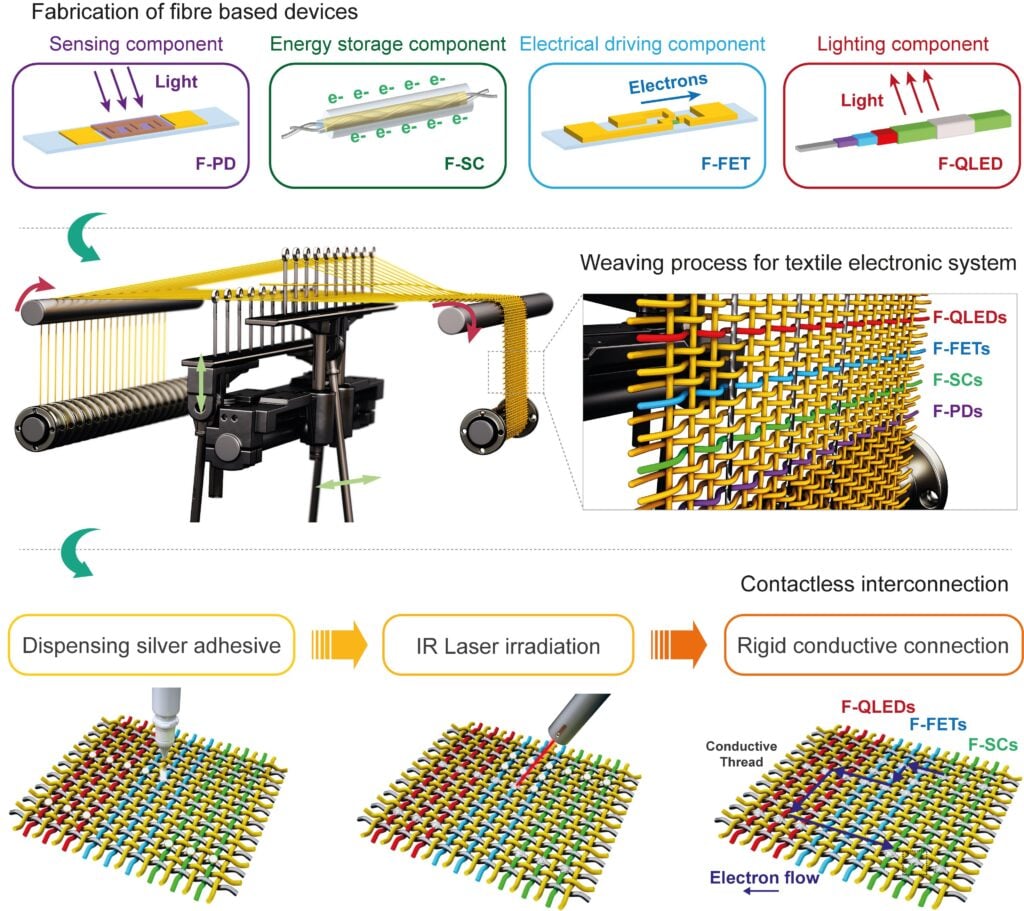

What’s exciting is that this innovation has the potential to make the production of flexible electronic devices more affordable and accessible. Smart fabrics have been making waves recently with cutting-edge advancements in textile displays and other electronic gadgets. However, there was a catch – producing these fabrics required specialized laboratory equipment or boutique microelectronic fabrication facilities, neither of which are practical for large-scale production. But worry no more; the Cambridge team has cracked the code to make smart fabrics compatible with conventional textile equipment like industrial looms.

The secret is coating the fibres with materials that can withstand stretching! The researchers created a game-changing smart fabric by weaving electronic, optoelectronic, sensing, and energy fibre components with conventional fibres. They even produced a 46-inch woven demonstrator display to showcase the capabilities of this fantastic material.

Working hand-in-hand with textile manufacturers, the team produced test patches of smart textiles of around 50×50 centimetres. This can be scaled up to larger dimensions and produced in large volumes.

That could mean flexible displays and monitors produced on industrial looms instead of specialized electronics manufacturing facilities. That could be much cheaper to produce, bringing us closer to a world filled with smart-textiles.

As Dr Sanghyo Lee, from Cambridge’s Department of Engineering, put it, “The result is basically an electronic system that is manufactured the same way other textiles are manufactured.” Can you imagine the possibilities? From smart homes and automotive industries to fashion and construction, these smart textiles have the potential to revolutionize various sectors.

The future of smart textiles is looking brighter than ever, thanks to the innovative minds at the University of Cambridge. This groundbreaking research paves the way for a world where our clothes and fabrics are more than just materials to cover our bodies but also interactive and intelligent companions that enrich our lives.

TLDR

- Cambridge researchers developed smart fabric that can be woven on industrial looms.

- Smart fabrics combine electronic, optoelectronic, sensing, and energy fiber components with conventional fibers.

- Production on industrial looms makes smart fabrics more affordable and accessible.

- Large, flexible displays and monitors can be made using this method.

- Smart textiles have the potential to revolutionize various industries, including fashion, automotive, and construction.

Published as “Truly form-factor–free industrially scalable system integration for electronic textile architectures with multifunctional fiber devices” in SCIENCE ADVANCES Vol 9, Issue 16