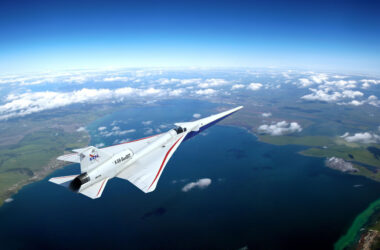

Reaction Engine’s Sabre engine – part jet, part rocket – is set to be put through its paces over the coming months.

The hypersonic engine could potentially reduce the trip time from London to Syndey from twenty-two hours to just four hours.

The European Space Agency has already signed off on the core-part of the engine design in a series of preliminary design reviews.

Reaction Engines Test Facility, Westcott, Buckinghamshire where the ESA completed design validation of Reaction Engine’s revolutionary air-breathing SABRE rocket engine

The engine is now set for a new phase of design testing over the next few months in Colorado, USA. This second round of testing will put the engines pre-cooler system through its paces. The engine relies heavily on its unique pre-cooler heat-exchange tech.

This next round of testing will allow Reaction Engine to then proceed to demonstrate the central section of the Sabre Engine on its own Wescott Space Cluster campus in Buckinghamshire in 2020.

The campus was once home to Britain’s post-war Rocket Propulsion Establishment which made a number of major contributions in the field of rocket science, including input on the rocket design for the Blue Streak missile and the propulsion systems on Chevaline warheads.

The engine should prove revolutionary for the UK space sector as it allows both ultra-fast point-to-point transport within the atmosphere and reusable vehicles to make the jump straight to orbit without the need for multiple rocket stages.

How does the Sabre Engine Work?

The engine works like a ‘normal’ jet engine for the first part of its flight.

However, once the engine hits Mach 5.5 – that is 5.5 times the speed of sound – it is able to move into ‘rocket mode’.

The engine can then propel itself up to Mach 25 and allow it to reach orbit.

The European Space Agency is being careful in auditing the technical development of Sabre as a mixed flight profile presents huge engineering challenges in managing the extreme stresses and temperatures applied to the engine.

The engine is only able to operate at these extremes thanks to a small pre-cooler heat-exchanger which is able to cool the hot air around the craft (which can reach temperatures around 1000°C) to -150°C in less than a hundredth of a second.

Reaction Engine’s successfully demonstrated the pre-cooler back in 2012 with ambient temperature. However, the tests in the US over the next few months will prove it can do the same at higher temperatures.

The pre-cooler (front-end of the engine) then feeds through to the core-combustion section in the middle (which is able to manage its heat and fluid flow through a smart thermodynamic cycle), and then uses a more traditional rocket design at its rear.

Reaction Engine has been backed by aerospace giants BAe Systems, Rolls-Royce and Boeing as well as receiving research and development support for the government.

Interested in seeing behind the scenes in the UK Space Industry. Check out our story “Britain in Space” – Born to Engineer talk to Photographer James Ball about documenting Britain’s thriving space industry“