Two construction companies, Synhelion and Cemex, have embarked on a groundbreaking collaboration to revolutionize cement production by harnessing the sun’s power, one of the most energy-intensive processes in the industrial world.

As global carbon emissions continue to be a pressing concern, the significance of such an initiative cannot be overstated. The collaboration between Synhelion, a clean energy company born out of the Swiss Federal Institute of Technology (ETH Zurich), and Cemex, a global construction materials giant, should set the stage for a paradigm shift in how cement, a fundamental building block of modern infrastructure, is produced.

The company uses solar radiation technology to produce synthesis gas, or syngas, which can achieve temperatures exceeding 1,500°C. Syngas are typically derived from waste biomass like food discards and animal byproducts. Synhelion’s method produces syngas directly from solar energy, eliminating the need for fossil fuels. This solar-driven process reduces carbon emissions and captures the remaining CO2 from calcination in a concentrated form.

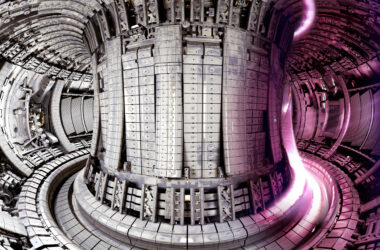

Clinker, a solid grey nodule produced using a blend of limestone and clay, is the most energy-intensive component of cement manufacturing. Traditional methods involve sintering clinker in cement kilns that operate at scorching temperatures and are primarily powered by fossil fuels. Synhelion’s technology has made it possible to replace this conventional method. Their solar energy system has successfully powered a clinker rotary kiln, marking a significant milestone in sustainable cement production.

A series of significant achievements have marked the collaboration between Synhelion and Cemex. At the start of 2022, the two companies unveiled the first-ever successful production of solar clinker. This was achieved through a small-scale batch process pilot, setting the stage for larger, more ambitious projects.

Producing clinker, typically requiring temperatures nearing 1,500 degrees Celsius, has historically been powered by fossil fuels. The recent milestones achieved by the partnership are not just limited to pilot projects.

The company announced in August that they have successfully scaled their technology to conditions that mimic real-world industrial operations. This achievement has paved the way for the potential industrial-scale implementation of solar-powered cement production.

Fernando A. González, CEO of Cemex, speaking to The Engineer, expressed his optimism about the advancements, emphasizing that solar cement is not just a vision but a tangible reality backed by rigorous research and testing. “I am convinced we are getting closer to the technologies that will enable net-zero CO2 cement and concrete production [..] the solid progress I see here proves that solar cement is not just a dream; it is achievable through continued collaboration and backed up by rigorous research and testing

This new technique has not gone unnoticed. The efforts to revolutionize cement production have garnered significant financial and strategic backing from various investors. Synhelion, in particular, has secured substantial funding, with a recent injection of 22 million Swiss francs (GBP 20 million) to scale up its solar-powered industrial energy platform.

The platform, which harnesses solar radiation to produce syngas, holds immense potential for decarbonizing heavy industrial operations. Recognizing this potential, several corporate investors have extended their support to Synhelion, eyeing the net-zero gains that this technology promises for the construction sector in the coming decades.

Among the notable backers are the Italian energy giant Eni and Mexican cement producer CEMEX’s CVC. Other significant investors include SMS Group, a supplier to industrial construction projects, automotive equipment maker AMAG, and national air carrier SWISS. The recent funding round also saw participation from CEMEX Ventures and other strategic investors.

In addition to financial backing, Synhelion and Cemex’s efforts have received a boost from the U.S. Department of Energy. A grant of $3.2 million was awarded to Solar MEAD, a joint project between the two companies, along with Sandia National Laboratories. This project aims to study conditions to maximize heat transfer to the raw cement mix, further advancing the cause of solar-powered cement production.

The engineering industry and the world will watch keenly as the two companies continue to develop this new tech. The promise of solar-powered cement production is now on the horizon, bringing the hope of a more sustainable and greener future.

TL;DR:

- Synhelion and Cemex collaborate to pioneer solar-powered cement production.

- Synhelion’s technology, originating from ETH Zurich, uses solar radiation to produce syngas for cement production.

- Successful production of solar clinker will be achieved in early 2022.

- The partnership has garnered significant financial backing, including a $3.2 million grant from the U.S. Department of Energy.

- Cemex’s “Future in Action” program aims for net-zero emissions by 2050, with solar-powered cement as a critical initiative.